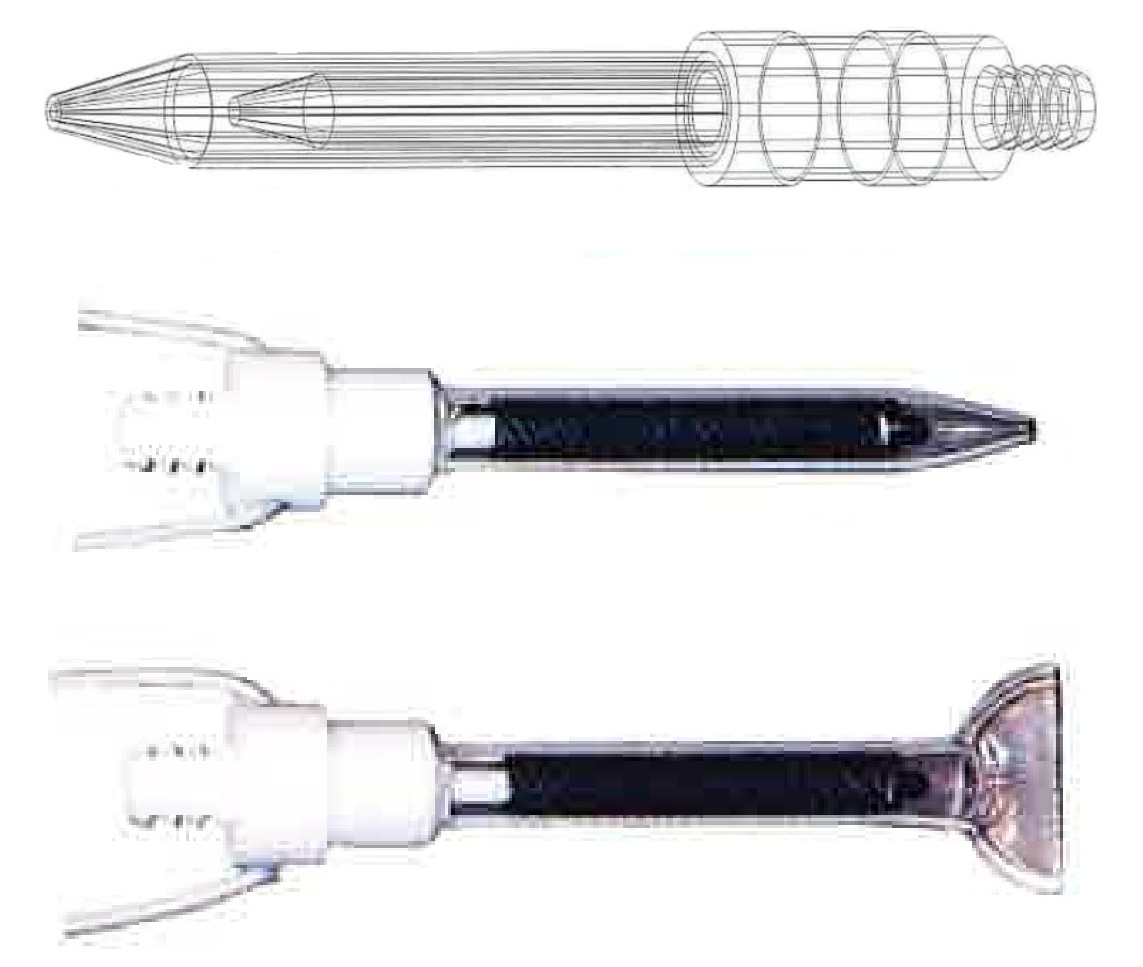

・Soldering of surface mount parts

・Heat source of heat shrink tube

・Heat source for caulking of thermoplastic resin

・Preheating of cans before printing

・Linear heating of coreless coils on coiling machine

・Heat drying of adhesives

・Silver brazing of medical devices

・Heating of liquids

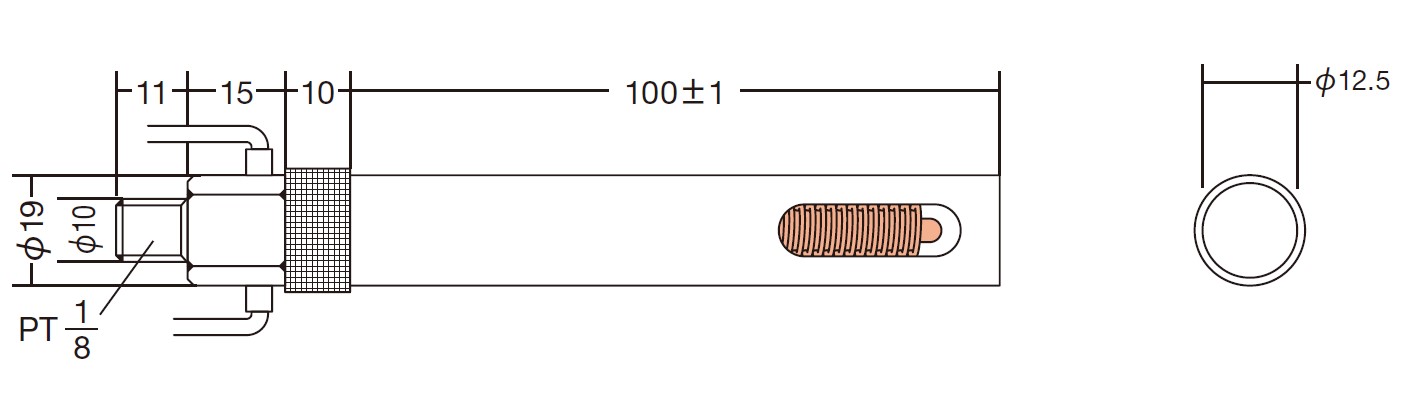

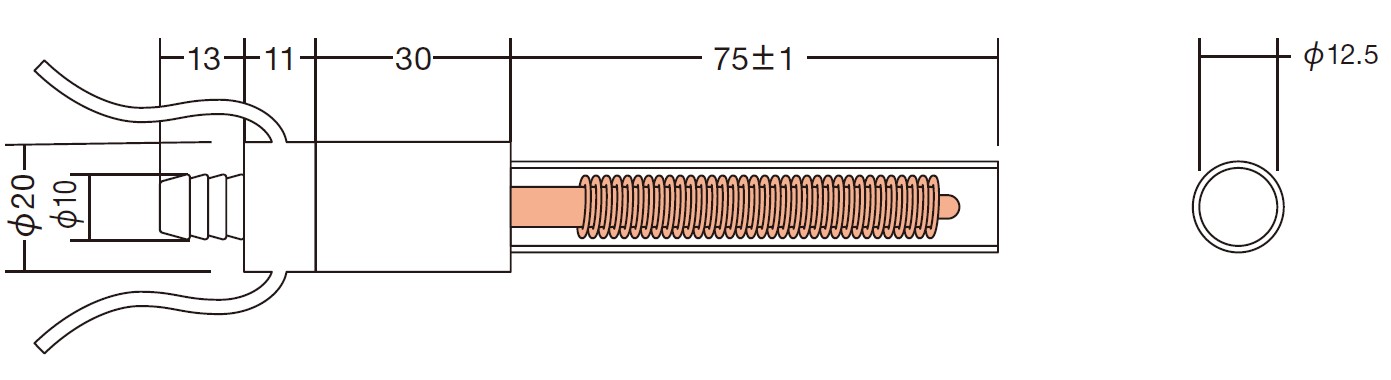

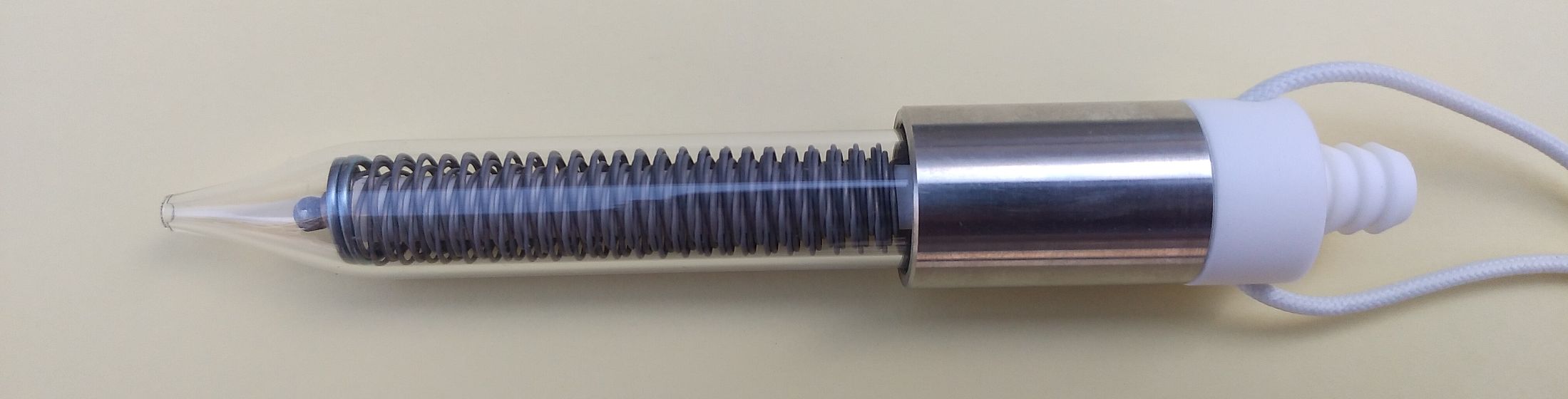

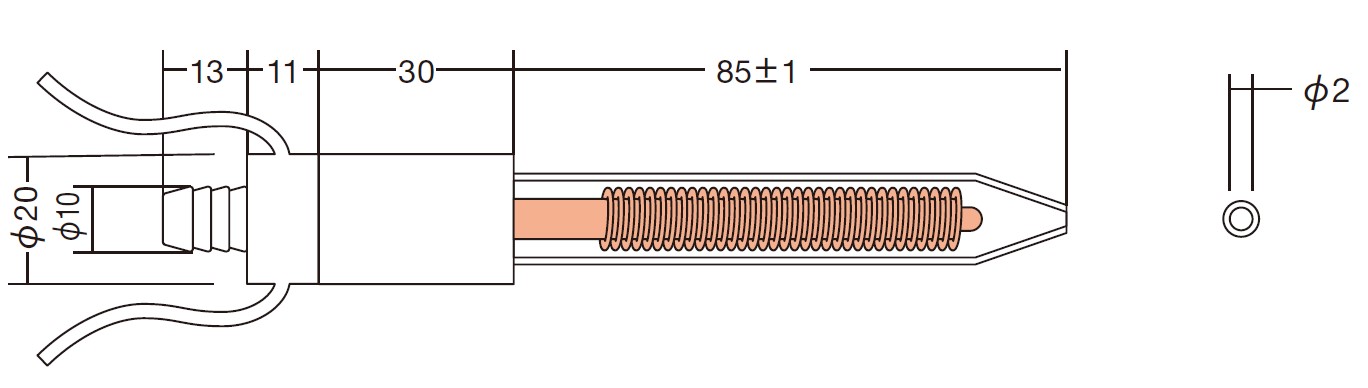

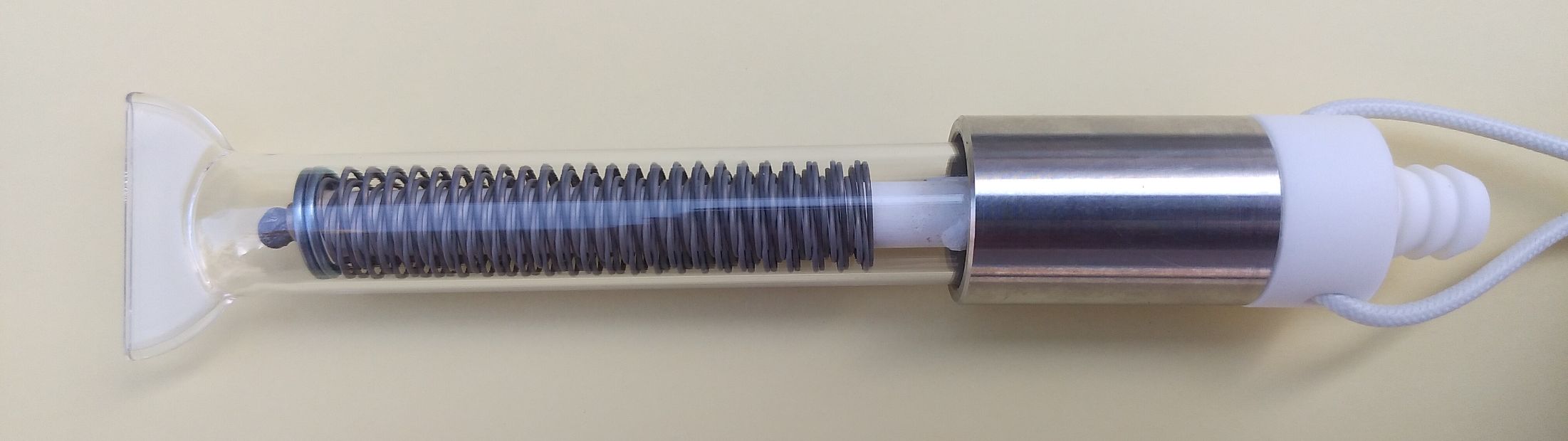

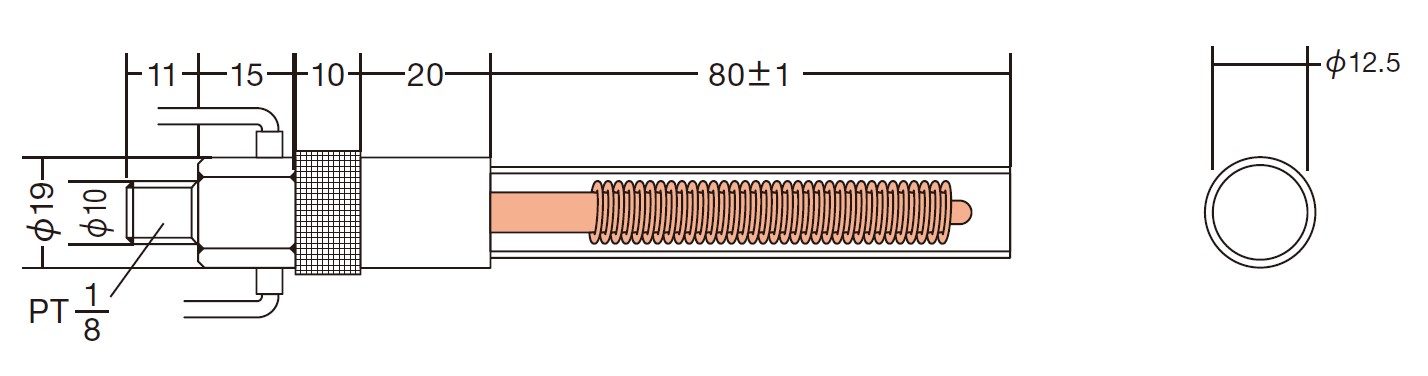

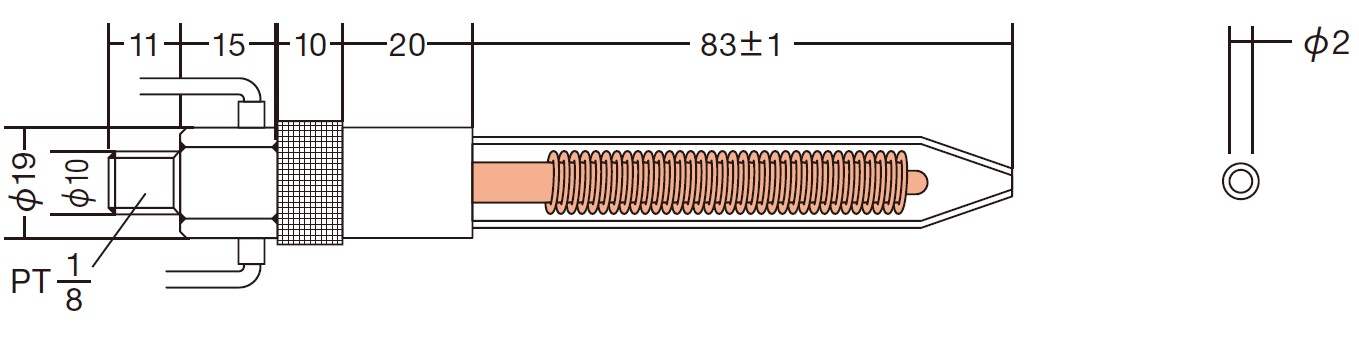

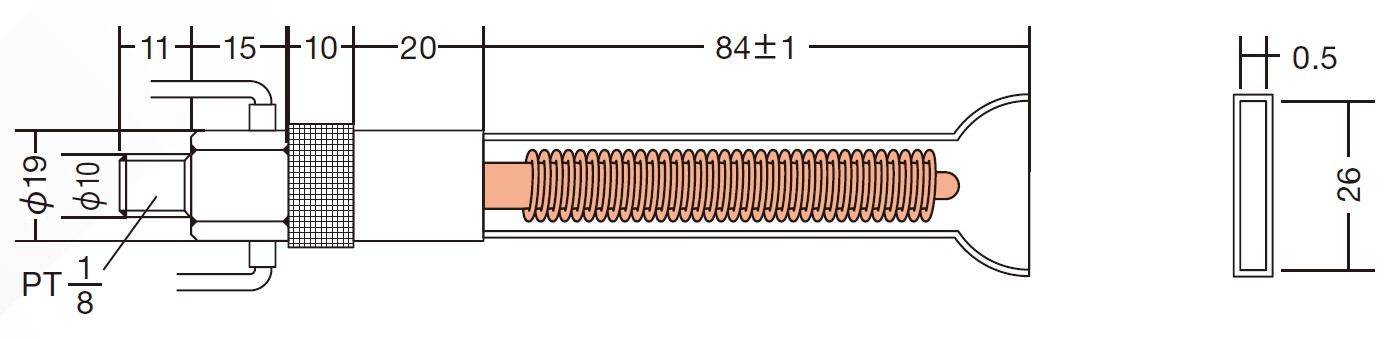

*In the range of AC100V-100W to AC200V-3KW we are prepared to make a customized NCH heater in accordance with your specific requirements for heater capacity, configuration, dimensions, materials, shape of glass tube.